Steiger ERP

Our software helps metalworking specialists Steiger track the work done by its various departments from customer relations to manufacturing.

Background

Steiger is a family business at its core, being involved in steel structure production, industrial construction and machining since 1994. In 2015 they hired us to develop a system that would automate their workflows and improve the reliability of their processes.

working hours

users

How we identified and resolved the problems

We had on-site interviews and discussions with Steiger's technical manager and some of the production workers to find out more about the process and about how each employee contributes to the end-result. During our discussions 3 main problems surfaced. This helped us focus on the features that mattered the most.

Creating offers was time-consuming and error-prone

ProblemOffers were put together manually with the help of multiple Excel spreadsheets, which contained over 50 criteria and complex computations.

SolutionWe worked closely together with the Steiger management and sales teams to eliminate variables and data duplication and to simplify the process as much as possible.

In the end, we managed to come up with a solution that correctly estimates labour costs and material needs based on available workload and stock levels.

Stock levels were unavailable

ProblemWe observed that there was no system to track leftover materials and most of it was eventually scrapped. This was a huge source of waste, which required and urgent solution.

SolutionWe set up a supply chain and inventory system which allows Steiger to qualify and review suppliers, make purchases, and keep track of their current stock levels.

Manufacturing times were not measured

ProblemWe found out that workers were not actively clocking time. Because they were wearing industry-grade protective gloves, working with the tablet PCs installed to track time was cumbersome. So they stopped using them, and management started missing out on essential production data.

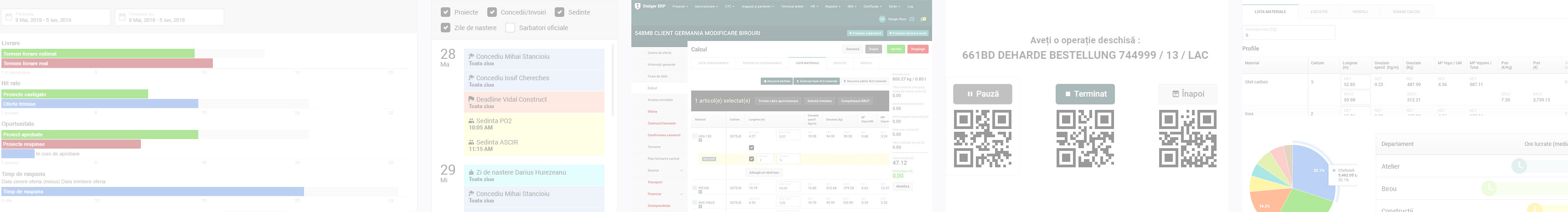

SolutionWe developed a QR code based system which allows workers to quickly track the manufacturing stage a product is in and the materials they're using. Daily timesheets are automatically generated.

Key takeaways

Get the opinion of everybody involved

One of the first problems we faced was that most of the employees were hesitant about using a new software.

Once we interviewed them and found out exactly what their pain-points were, it was much easier for us to come up with a solution that they would embrace.

Management is not always right

A lot of management's ideas were very different to those of their employees. But it was the employees who were going to actually use the product.

We quickly learned that for the success of the project, it was crucial to align the opinion of all the stakeholders.

Designing for all environments is hard

Creating a user-interface that would work well in the offices, on the move on mobile devices and next to the production lines as well, is just as complicated as it sounds.

We called on an experienced user experience designer to help us. Together we put in multiple hours of research and developing a design system to make sure all the essential data is conveniently available.

Expand gallery

Expand gallery

Project quotes

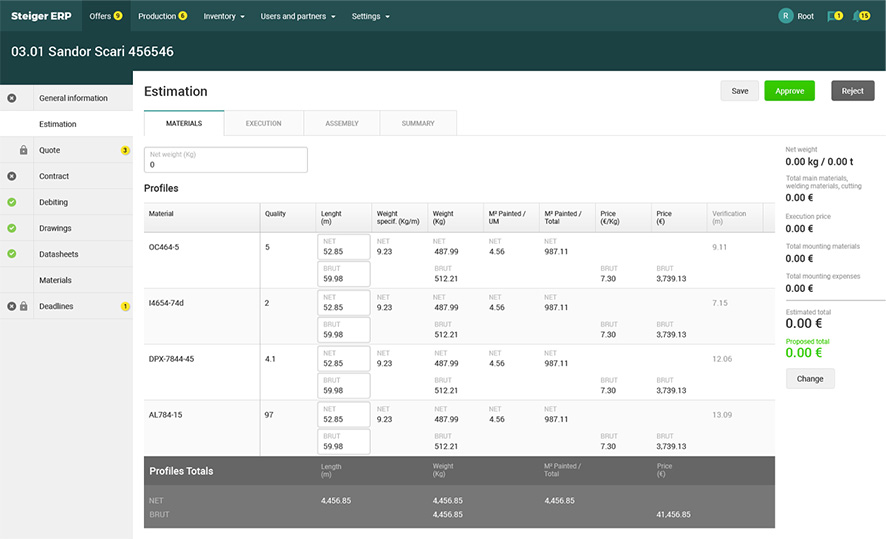

Most of Steiger's projects are long and complex. So is the process of generating exact price quotes.

A lot of factors have to be taken into consideration: materials, different types of manual and machine processing, shipping and assembly.

Thanks to the new quoting module, we reduced the time necessary to quote a project by 4x times compared to the old Excel spreadsheets.

Inventory and supply chain

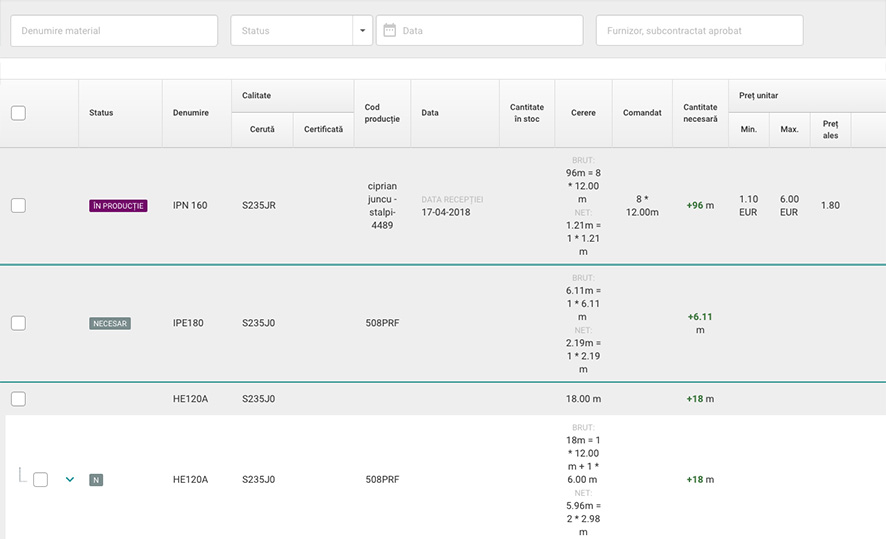

Once a project starts, the first step is the procurement of materials. The inventory and supply chain module helps Steiger keep track of the acquisition process.

The inventory system tracks stock levels, material quality and certifications and forecasts material use based in the projects in the sales pipeline. It also hints operators when a material on stock could be used for a project.

The supply chain system automates the purchasing workflow: it sends requests for quote to suppliers, allows them to upload price lists and product availability and handles supplier quality assurance.

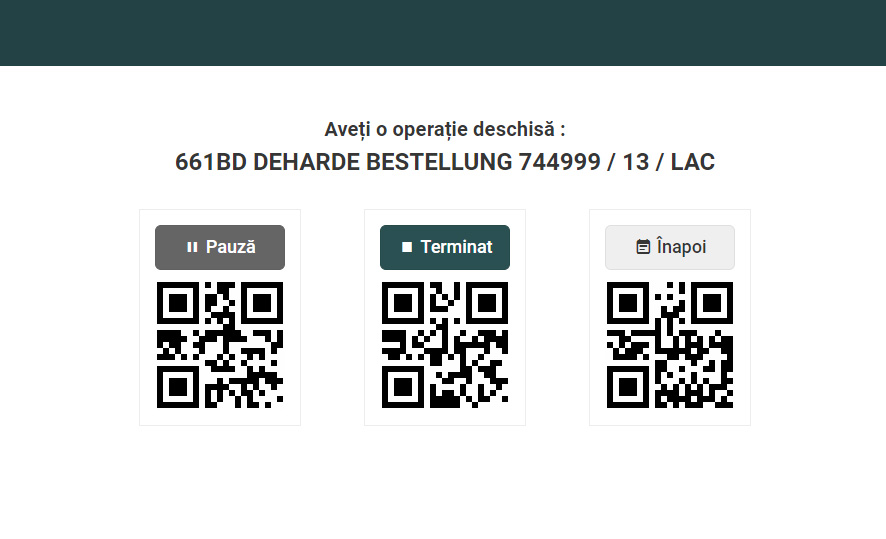

Time tracking

Once execution starts, a lot of processes have to be tracked: manual labor, machine processing, material changeover and maintenance times.

For tracking manual labour and material use we implement a QR code based system, which allows workers to easily track time when working in the production hall.

We also gather information regarding machine production data to compute average material changeover times and schedule preventive maintenance.

Dashboard

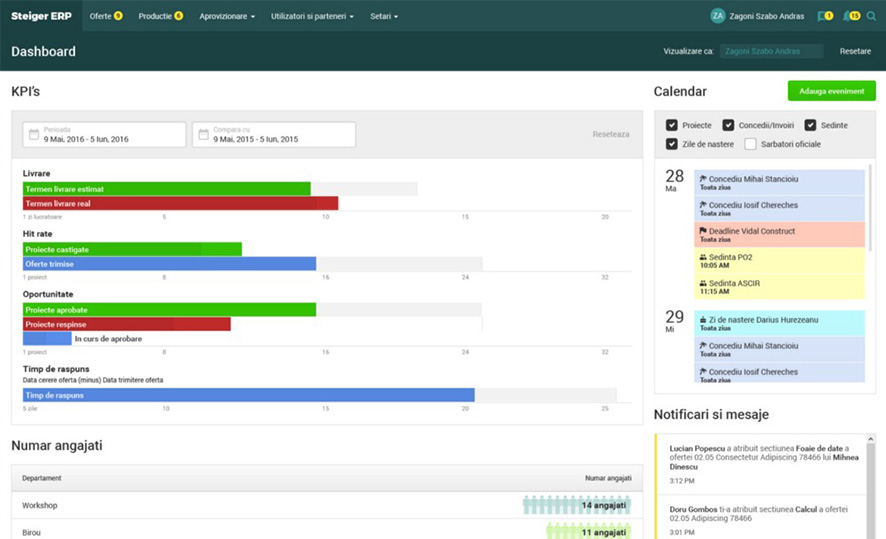

The dashboard is a general manager's dreamland, with customizable KPI's galore.

Just to name a few: lead conversion data, project delivery rates (in budget and in time), production data, HR reports and financial forecasts.

It's also the place for the company-wide calendar, notifications and the individual task lists.